Magnetron reactor

Overview

In power systems, the safety, reliability and economy of grid operations are very important. It is important to adjust the reactive power of the grid quickly and reasonably, adjust the regulation of the AC grid and adjust the system voltage, reasonably distribute the current and limit the overvoltage of the grid. In recent years, with the rapid development of metallurgical, petrochemical, electrified railways, wind power and new energy industries, as well as the continuous expansion of the scale of power grids, various electrical equipment connected to the power grid consumes a large amount of reactive power, reactive power shortage and voltage. The problem of large fluctuations has become increasingly prominent. In order to ensure the safe and stable operation of the power system, our company launched the CPSVC dynamic reactive power compensation device.

Working Environment

1. installation location: indoor/outdoor

2. Altitude: 1000m and below (≥ 1000m with high prototype)

3. ambient temperature: -40 ° C ~ +55 ° C

4. monthly average relative humidity: 95% (at 25 ° C)

5. earthquake resistance: ground level acceleration of 0.2g, vertical acceleration of 0.1g. Test according to standard, safety factor ≥ 1.67

How it works

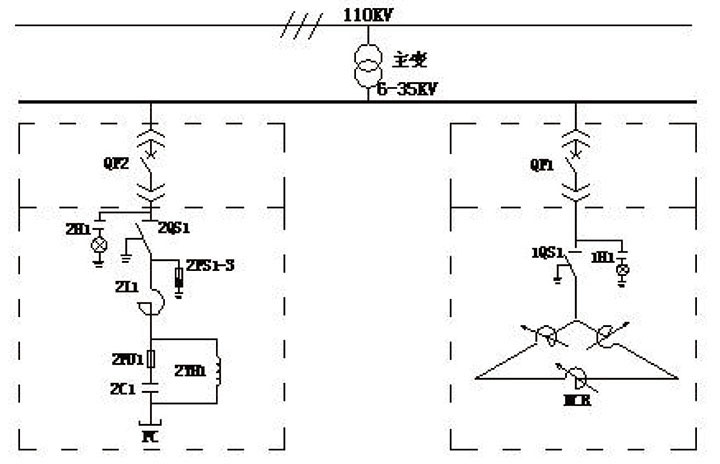

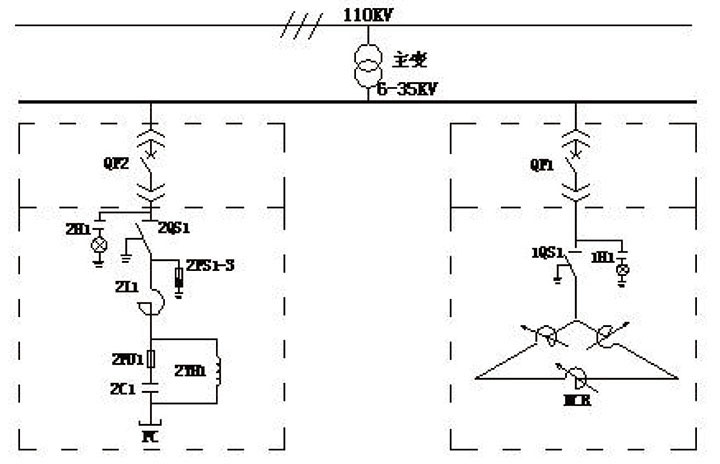

CPSVC consists of a parallel fixed capacitor bank and an advanced magnetron reactor (MCR). The capacity of the magnetron reactor is steplessly adjustable, and it can automatically track and compensate the load reactive power and stabilize the bus voltage. The FC branch provides fixed guest reactive power to the system. The control part of the MCR collects the system bus voltage, load current and MCR branch current analog signal. After the calculation of the control algorithm, the thyristor firing angle is obtained, and the analog quantity is generated by photoelectric conversion. The signal is fixed to form a trigger pulse for controlling the conduction angle of the thyristor, and then the signal is shaped and amplified. Phase shift control is performed on the conduction state of the thyristor to dynamically adjust the inductive reactive power of the MCR branch. In order to balance the excess guest reactive power, the system reactive power value is guaranteed to be a constant.

The formula is as follows:

QL+OR-QC=QS (or a constant)

where:

QL is the inductive reactive power value of the load (variable)

QR is the inductive reactive power value of the MCR loop (variable)

QC is the capacitive reactive power value of the fixed capacitor and filter branch (fixed or segmentable)

QS is the reactive power value supplied by the system

Product model

Performance Features

◆ Wide range of use: applicable voltage level is 6kV-220kV, with the ability to operate in harsh environments;

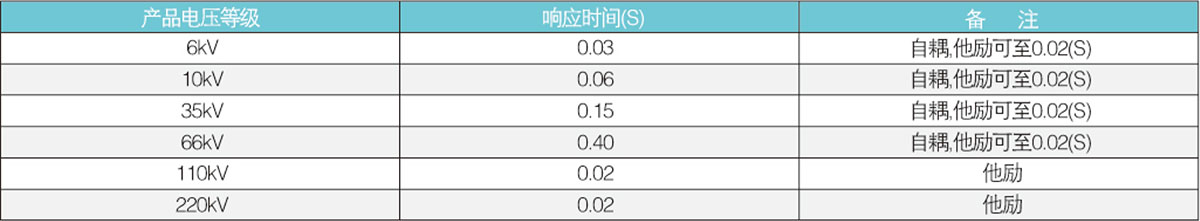

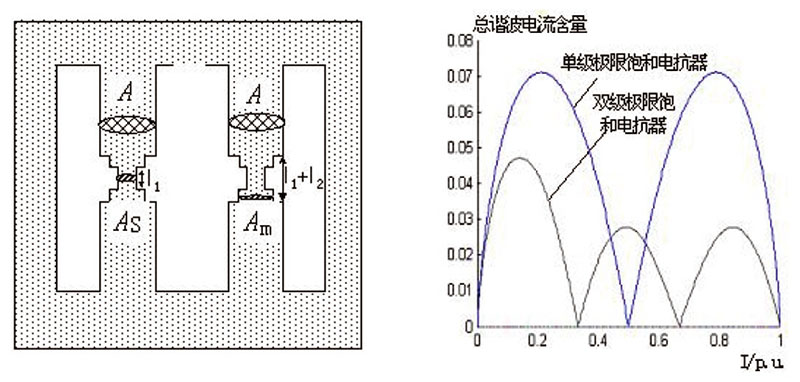

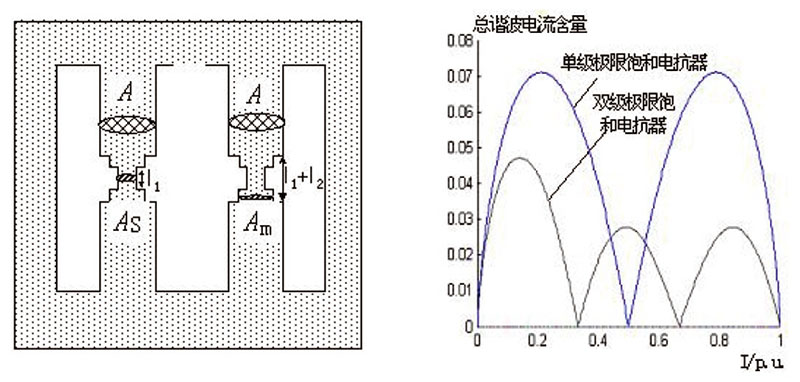

◆ Advanced technology: the use of double magnetic pole limit saturation and dynamic magnetic flip technology, resulting in small harmonics, fast response;

◆ large adjustment range: by controlling the conduction angle of the thyristor for automatic control, continuous adjustable reactive power can be achieved, the adjustment range is 1%-100%; the power factor is continuously adjusted, the adjustment range is 0.8 -0.999 ;

◆ Strong overload capability: 100% overload for 30 seconds, 40% overload for 30 minutes;

◆ High reliability: can achieve basic maintenance-free operation for decades;

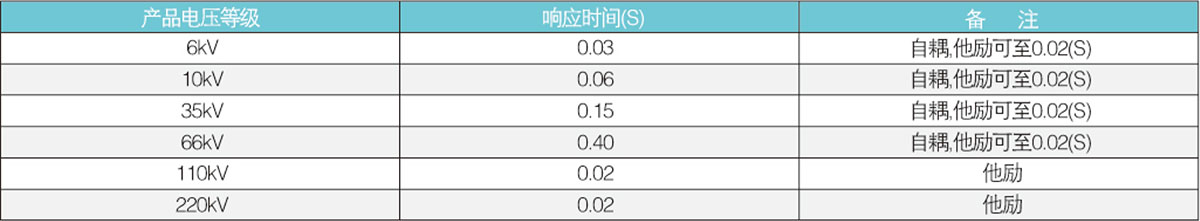

◆ Fast response: MCR dynamic response time for different voltage levels is as follows:

◆ low loss: large capacity MCR, loss less than 0.5%, generally can achieve 0.8-1.5%;

◆ Strong overpressure: with natural automatic pressure limiting;

◆ Small footprint: easy to install, the equipment is oil-immersed, outdoor installation. Natural cooling;

◆Environmental pollution is small: Nopo is small, no pollution to the power grid, no adverse impact on the existing capacitor bank, easy to use existing equipment for transformation, no electromagnetic pollution to the environment and human body.

Main device components

CPSVC device consists of control and protection system, magnetron reactor, filter capacitor bank and various accessories.

1. control protection monitoring system

DSP-based valve control to achieve parallel processing of digital control signals, dynamic response, high control accuracy, real-time control calculation; system anti-interference ability, reliable protection; microcomputer real-time monitoring MCR The operation status of the base sluice tube, timely alarm and protection, make the equipment run reliably: the control system generates the trigger pulse required by the thyristor according to the control strategy through the measurement, comparison, amplification, phase shift triggering, and controls the trigger angle of the thyristor. The current of the reactor reaches the required reactive power; the whole control and monitoring system has strong anti-interference ability; the control is flexible, and various control modes such as three-phase simultaneous control, phase separation control and three-phase balancing can be realized; With remote operation and automation system interface functions, it can be unattended.

2. magnetron reactor

The magnetron reactor is one of the controllable reactors, the core has a section with a small load area, and only a small section of the magnetic circuit is saturated in the entire capacity adjustment range, and the remaining sections Both are in an unsaturated linear state, and the capacity of the reactor is changed by changing the degree of path saturation of the fractional surface. The magnetron reactor has a simple structure and low cost, and has great application potential for improving the power transmission capacity of the power grid, adjusting the grid voltage, compensating for reactive power, and limiting overvoltage.

3. FC branch mainly includes the following not available

FC branch routing several sets of monotonic wave device and a set of high-pass filters. Since the capacitor and reactor series circuit is a low impedance loop in the tuned state, it has the function of absorbing harmonics and providing the reactive power required by the system. Mainly composed of capacitors, reactors, surge arresters, spray fuses and discharge coils.

Technical parameters

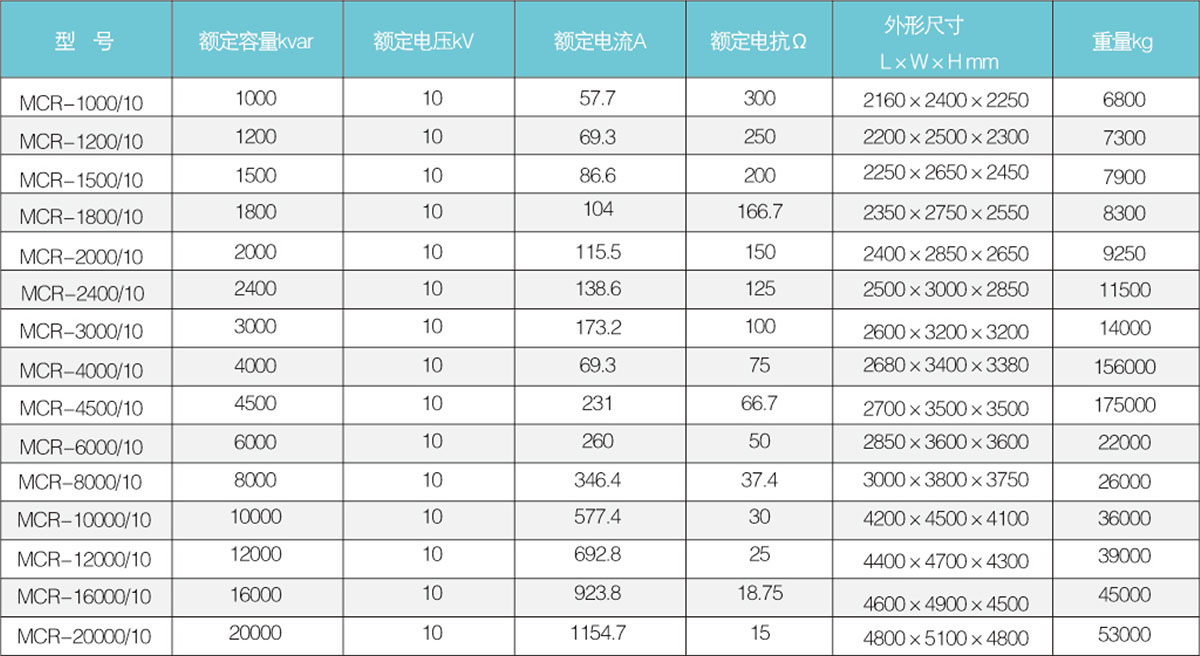

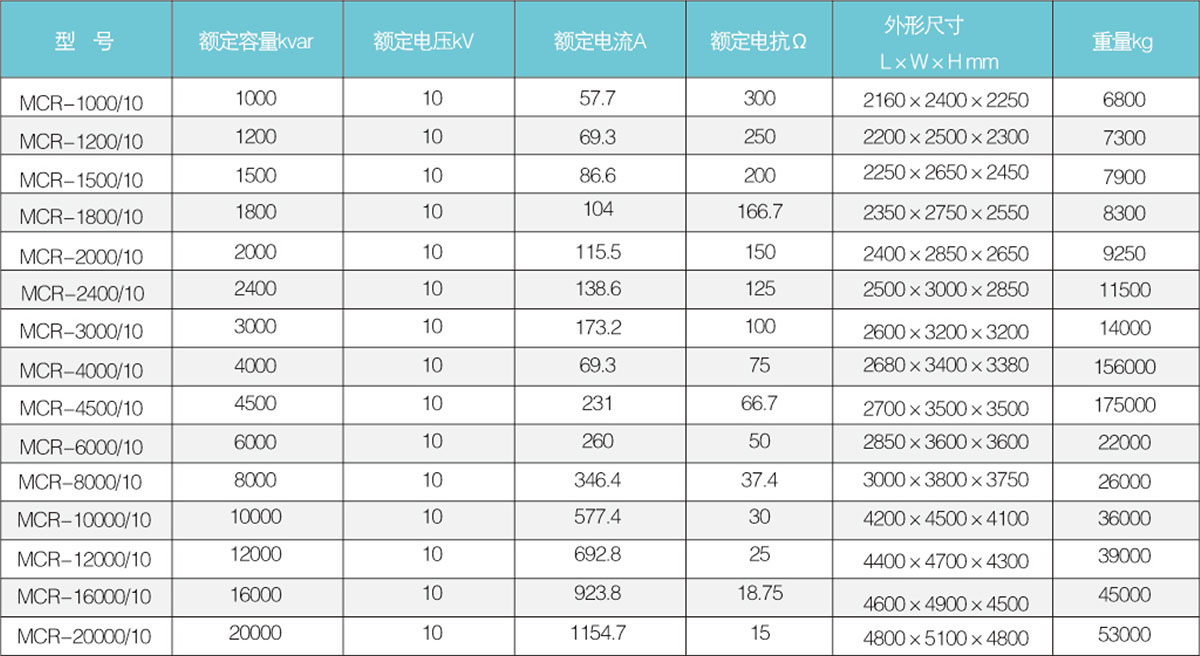

1. 10kV oil immersed magnetron shunt reactor connection group: delta connection

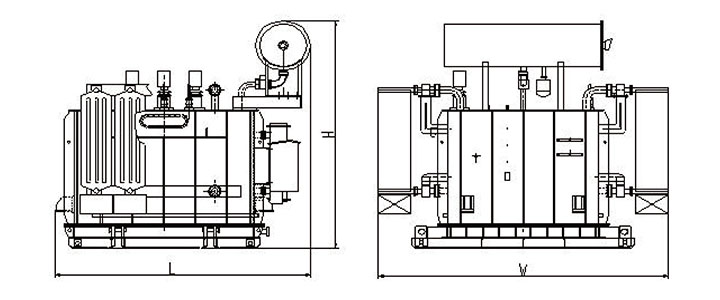

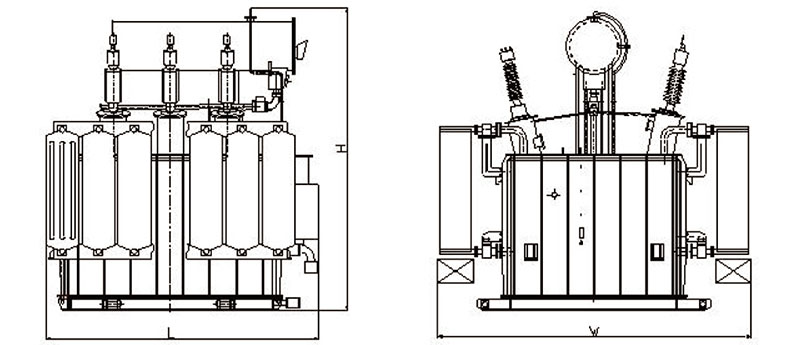

10kV oil immersed magnetron shunt reactor MCR shape:

35kV, 66kV oil-immersed magnetron shunt reactor connection group: delta connection method

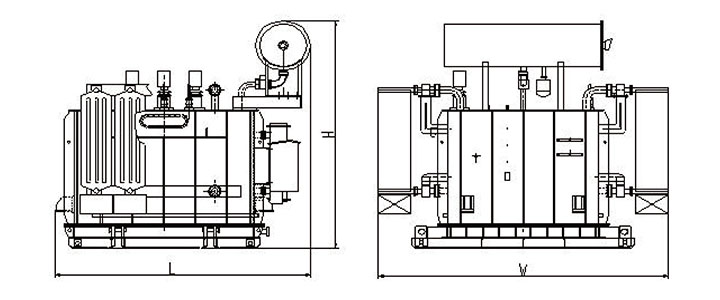

35kV oil immersed magnetron shunt reactor MCR profile :

Note: 1. Dimensions and weights are only used as design references. Depending on the situation, the actual product size may differ slightly from the above dimensions;

2. The installation of the MCR on site and the foundation construction refer to the design of the oil-immersed transformer.

CPSVC technical description and performance advantages comparison

MCR's unique magnetic pole double-saturation structure ensures low harmonic content

The advantages of MCR and TCR performance are as follows:

Apply the City

CPSVC type dynamic reactive power compensation device is mainly used for 6- 220KV power system, which can realize reactive power dynamic compensation, improve power factor, stabilize voltage, and filter harmonics to improve the grid. Power Quality. The device is currently widely used in coal, electrified railway, steel, wind power and other industries, and the power saving effect is obvious.

1. electric arc furnace

Electric arc furnace due to unstable arc resistance value, three-phase imbalance and other reasons, the arc furnace damage to the power grid mainly: the production of Novo is rich in components, and the content is large, its main Norwave current The composition is 2-7 times, of which 2, 3, 5 times maximum, the derivative power grid is seriously three-phase unbalanced, generating negative sequence current, there is severe voltage flicker, and the power factor is low.

The solution to the above problem is that the user must install a dynamic reactive power compensation device with fast response. The CPSVC system has a fast response time and can meet strict technical requirements. It can quickly supply reactive current to the arc furnace and stabilize the bus grid voltage, increase the output of the system active power, improve production efficiency, and minimize the impact of flicker. The phase separation compensation function of CPSVC can eliminate the three-phase imbalance caused by the electric arc furnace. The filtering device can eliminate harmful high-order novo waves and improve the power factor by providing guest reactive power to the system.

2. long-distance power transmission

Power system is currently tending to high-power grid, long-distance transmission, high energy consumption, forcing transmission and distribution systems have to increase improvement measures. CPSVC can significantly improve the transmission and distribution performance of power systems. Under different grid conditions, in order to maintain a balanced voltage, CPSVC can be installed at one or more appropriate locations in the grid to achieve the following objectives: Voltage: Reduce transmission loss, increase transmission capacity, maximize efficiency of existing power grids, increase transient steady-state limits, increase damping under small disturbances, and buffer power oscillations.

3. rolling mill system

Rolling mill is a reactive impact load, causing the following effects on the power grid: low power factor: causing voltage fluctuations and voltage drops. In severe cases, the electrical equipment is not ready for normal operation, reducing production efficiency: load transmission Harmful high-order harmonics are generated in the middle, and high-order harmonics, mainly represented by 5, 7, 11, and 13 times, cause severe distortion of the grid voltage. The CPSVC device can solve the above problems well, keep the bus voltage stable, filter out harmonics, and improve the power factor.

4. coal mine hoist

coal mine hoists mostly use DC motor drive, short working cycle, fast response, large fluctuations in reactive power, will have the following effects on the grid during operation: causing grid voltage drop and voltage fluctuation, power factor Low, rectifying devices generate a large number of higher harmonics, and the rapid response of the CPMSVC device can perfectly solve the above problems.

5. wind farm

In the wind farm, voltage and reactive power are affected by wind speed fluctuations, and some inductive reactive power is often needed to compensate the line charging power. If the fixed or grading switching capacitor bank is used to compensate the system Reactive power, improve power factor, this method can only provide capacitive and reactive, but can not achieve rapid dynamic adjustment with the change of wind speed, easy to cause reactive power to the system, voltage rise, hazardous electrical equipment and system stability. The CPSVC system can quickly and accurately perform capacitive and inductive reactive compensation. It can completely solve the problem of reactive power reversal while stabilizing the bus voltage and improving the power factor. And when installing a new SVC system, you can make full use of the original fixed capacitor bank, just increase the part of the magnetron reactor, and achieve good results with less investment, which is a suitable choice for improving the power quality control of wind farms.

6. power locomotive power supply

Electric locomotive transportation mode in the protection of the environment also caused a serious "contamination", the single-phase power supply of the locomotive caused a serious three-phase imbalance of the power supply network and low power factor, and Produce negative sequence current. The current solution to this problem is to install CPSVC at appropriate locations along the railway to improve the power factor and resolve the three-phase imbalance.

OrderNeedKnow

1. system diagram and parameters: equipment rated voltage, rated current, operating voltage, etc.;

2. the total power and average power factor, the target power factor, or the reactive power compensation capacity required for normal operation when the equipment is in normal operation;

3. incoming mode, environmental conditions, order quantity, delivery time, delivery method, transportation mode, etc.;

4. users can order according to our company's model, capacity, specifications, quantity, but also provide parameters and requirements by our company to determine the specifications and models;

5. installation site: indoor, outdoor, size;

6. other special technical requirements.